Complete Aeration Systems

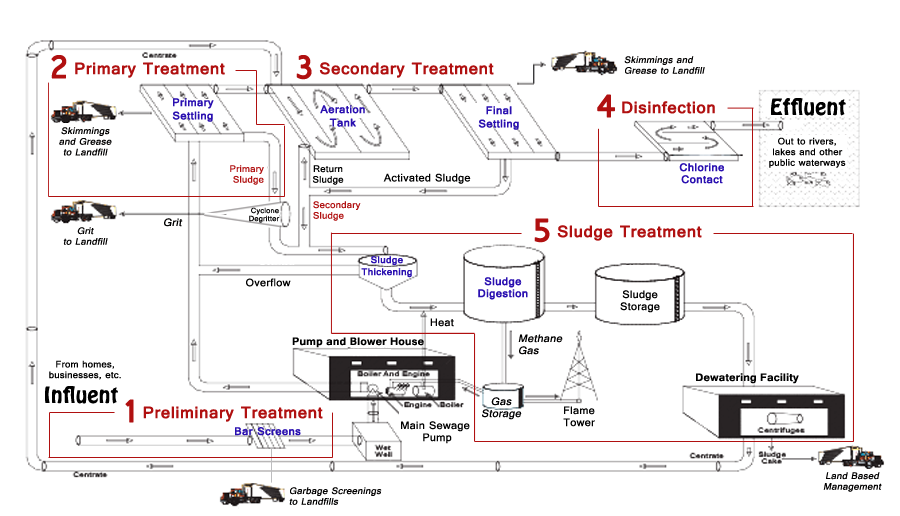

Wastewater and water treatment aeration solutions can be custom-tailored to complement the specific needs and challenges of your wasterwater treatment processing system. When considering improvements, repairs or upgrades, it is essential to ensure that you are getting the most out of your treatment plant and meeting your wastewater treatment needs.

Mooers Products (MPI) has over 25 years experience in designing, installing and retrofitting complete diffused aeration systems for wastewater treatment facilities. Our engineering services range from upgrading and repairing components and systems to installing new systems or replacing outdated systems.

Aeration System Design Considerations

Every industrial water system is unique, not only in the production operations it supports and the sources of water it receives, but also in the degree of inherent variation encountered due to the factors listed below:

Nitrification Challenges — Some processes (such as nitrification) require a higher solids residence time (SRT). Although cost- and space-prohibitive, solutions can include larger biological reactors and secondary clarifiers. To accommodate your facility’s needs for nitrifying bacteria growth, there are various techniques that can be implemented to reduce the biological reactor sizes.

- Upstream Organic Matter Removal

- Plug Flow Aerobic Zones

- Improvements in Sludge Settling

- Improved Wastewater Characterization Techniques

- Seeding Nitrifiers into the process

- Step Feeding

- pH Control

- Overall System Integration

Mixing Action versus Air Flow Rate — Depending on your processing equipment, the diffused aeration mixing action may or may not be independent of the air flow rate. There are optional solutions to consider that will enable proper oxygen transfer rates without compromising the air flow rates within the same tank.

Water Flow and Velocity — Greatest efficiency is achieved when water flow is countercurrent to rising air bubbles.

Additional Considerations

- Dissolved Gas Reduction

- Iron and Manganese Removal

- Volatile Organic Concentrations

- Non-Volatile Organic Compounds

- Temperatures

- Process Demands

- Evaporation Rates

- Water Characteristics (such as hardness, suspended solids, pH swings)

- Influent and Effluent Quality

At MPI, we implement various quality methods for monitoring, evaluating and improving our customers’ water treatment processes and systems. Not only do wastewater systems vary considerably, their water characterizations can change over time (examples include abruptness and degree of change, water losses, production rate changes and chemical feed rates). These and other variables are considered during our initial consultation with clients. To understand our quality mindset, please refer to our Quality Assurances. Or contact our Engineering Services today for more specific questions or customized assistance.

“We specialize in diffused aeration systems, retrofits and processes.”

NEXT ► Flexcap™ Aeration Systems